People and businesses have faced a barrage of challenges this year – the fallout of a multitude of global issues. But at Target Timber, we’re optimists and while there are still some obstacles ahead, we want to look at the positives for our business and the wider timber frame industry.

We’re pleased to say that Target Timber Systems has had another successful year of growth. Like many timber frame manufacturers, we had some initial concerns earlier this year about whether our timber supplies might be affected by the Ukraine conflict, but our stock levels have remained strong thanks to our much-valued suppliers.

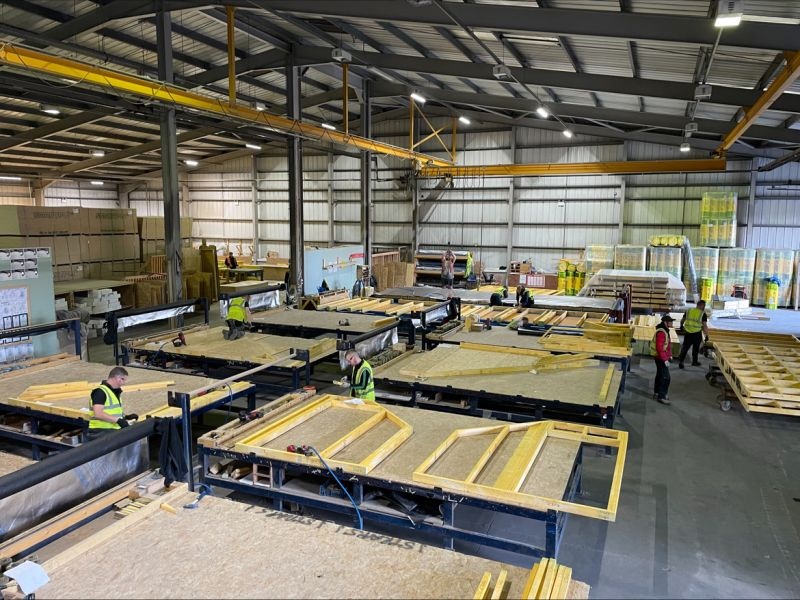

New closed panel timber frame systems

Following investment in new machinery and production processes, this year we were excited to introduce our new fully factory-assembled closed panel timber frame systems.

With standard u-values as low as 0.17 W/M²/K, the panels easily meet Part L Regulations and offer a superior quality, thermally-insulated solution that can be quickly assembled on site, further reducing construction times and customer costs.

Expanding into new regions

Target Timber typically supplies timber frame systems to customers right across the South of England, throughout Wales, and across London and the Home Counties.

This year we’ve not only continued to fulfil orders from our long-term customers, but we’ve seen an increase in orders from customers with housing development projects in Suffolk, Cornwall, Channel Islands and Wales.

New partnership to meet growing demand

In June this year, we announced an exciting new partnership with timber frame construction specialists ECO-SPACE. Together, we are better positioned to meet the increasing demand for timber frame systems for customers in Devon, Cornwall, and the Channel Islands.

Our predictions for timber frame demand in 2023

Growth in the construction industry appears to have been somewhat sluggish this year due to all of the aforementioned issues, along with a shortage of skilled workers and materials.

The good news however is that timber is going to play a big role in construction in the coming years. It is sustainable, durable, and always aesthetically beautiful which is why it is increasingly being specified for new buildings requiring natural architectural design features.

The demand for timber frame systems is already growing, thanks in part to new Part L Regulations that direct builders to adopt new methods of construction in order to address carbon reduction and energy saving.

We are also starting to see more enquiries from construction companies who are looking to use timber frame systems for the first time. This tells us that the benefits, in particular the cost-savings, of timber frame is beginning to resonate with more traditional masonry builders.

There’s still a long way to go in terms of education, but with the government behind the push for off-site manufacturing and the use of timber in order to cut carbon emissions in construction, there’s likely to be real traction in the coming years.

A sustainable, low-carbon future for construction

As a long-term manufacturer and installer of timber frame systems, we’ve always believed that one day, off-site manufacturing and the use of timber as a construction material will be the norm.

For now, we will continue to promote the glaringly obvious benefits of building with timber frame systems and do all that we can to educate and support our colleagues in the construction industry.

The future is bright. The future is timber.