There are many advantages to Timber Frame construction, but probably its best-known quality is its environmental excellence. Timber Frame has long held prime position in the eco-builders hall of fame. Housebuilders, developers and designers all know Timber Frame is a lot more green than grey.

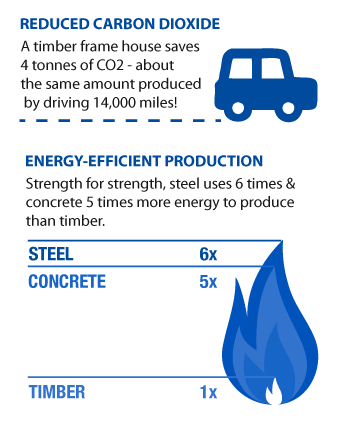

For example, a typical 100 square metre two-storey detached Timber Frame home built to the latest Building Regulations contains 5-6 cubic metres more wood than the equivalent masonry house. This means that every Timber Frame home we build saves about 4 tonnes of carbon dioxide (about the same amount produced by driving 14,000 miles). If all new houses built in the UK since 1945 had been Timber Frame, then more than 300 million tonnes of carbon dioxide would have been saved. To put this into context, consider the fact that, at current rates, it will take us another 200 years to achieve this sort of saving using the Governments latest energy regulations for new homes. When designers and developers decide to build with Timber Frame construction, they make a positive contribution to tackling climate change. The benefits dont stop at the point of a homes completion on site. Using a standard 140mm stud Timber Frame system achieves U-values between 0.30 and 0.27 using readily available and standard insulation – and using higher performance insulation and insulating breather membranes can boost these figures even more. This means significant carbon savings in the homes day to day use, as well as financial benefits from lower running costs.

A Timber Frame home is a warm, comfortable and safe place in which to live – and what more could you ask from a home that is also helping to reduce our carbon footprint. A thriving Timber Frame industry means the need for well run, sustainably managed forests, full of trees that soak up carbon dioxide within their core and keep it locked inside.

PRACTICAL

- Construction times are reduced using Timber Frame techniques by as much as one third.

- Impact of inclement weather is reduced as construction need not stop in periods of rain, frost, snow etc.

- Programme of following trades is easier.

- Timber Frame offers a lighter form of construction which can be of benefit to foundations particularly where poor ground conditions prevail.

- Improved sound insulation compared with alternative construction methods, particularly at separating walls.

- Higher thermal insulation at an economic price when compared with alternative construction methods.

- Greater accuracy and a better standard of finish after handover.

- Timber Frame is a dry form of construction so there is no drying out period. You will not get drying out cracks common in wet construction.

- Adequately responds to environmental issues related to energy use during production and after construction.

WHOLE LIFE

- Wood is effectively a carbon-neutral material (even allowing for transport).

- Timber Frame has the lowest CO2 cost of any commercially available building material.

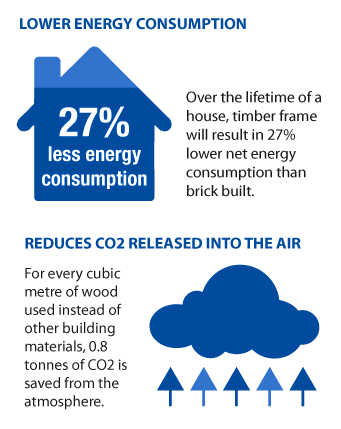

- For every cubic metre of wood used instead of other building materials, 0.8 tonne of CO2 is saved from the atmosphere.

- Processing timber is not a gas-guzzling procedure either. 77% of the energy used in the production of wood products comes from wood residues and recovered wood.

- Converting timber into a useable building material takes far less energy and creates minimal pollution compared to other mainstream alternatives such as aluminium, steel, concrete and brick.

- Strength for strength, concrete uses 5 times (and steel uses 6 times) more energy to produce than timber.

- Waste wood can be easily recycled as can the wood from products once they reach their “end of life”.

ENVIRONMENTAL

- Timber is an organic, non-toxic and naturally renewable building material.

- Although worldwide, deforestation remains a significant issue, it is not caused by the European construction industry which mainly uses softwood.

- Over 90% of all wood consumed in Europe is sourced from European forests.

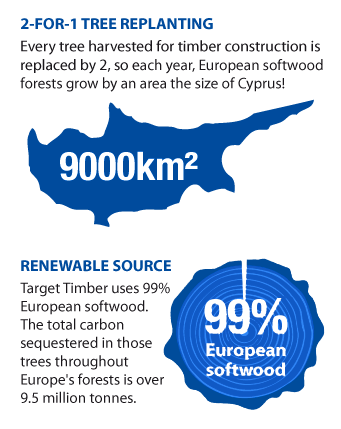

- UK Timber Frame uses 99% European softwood. The total carbon sequestered in those trees throughout Europe’s forests is over 9.5 million tonnes.

- The more wood we use, the more our forests grow, because in Europe we are committed to planting more trees than we harvest.

- Every year our forests grow by over 3,500 square miles – equivalent to an area the size of Cyprus.

- Forests act as huge carbon sinks. The total carbon sequestered in Europe’s forests is over 9.5 million tonnes.

- Mature trees, however, absorb far less carbon dioxide and produce less oxygen than those at earlier stages of growth. So the harvesting of older trees for construction purposes, and their replacement with saplings – two planted for every one harvested in Scandinavian forests – ensures a constant cycle of CO2 absorption and oxygen production.

MANUFACTURING

- Wood is effectively a carbon-neutral material (even allowing for transport).

- Timber Frame has the lowest CO2 cost of any commercially available building material.

- For every cubic metre of wood used instead of other building materials, 0.8 tonne of CO2 is saved from the atmosphere.

- Processing timber is not a gas-guzzling procedure either. 77% of the energy used in the production of wood products comes from wood residues and recovered wood.

- Converting timber into a useable building material takes far less energy and creates minimal pollution compared to other mainstream alternatives such as aluminium, steel, concrete and brick.

- Strength for strength, concrete uses 5 times (and steel uses 6 times) more energy to produce than timber.

- Waste wood can be easily recycled as can the wood from products once they reach their “end of life”.

WHAT DOES MY TARGET TIMBER BUILD INCLUDE?

All our timber frame buildings are supplied complete with all of the materials you need to complete the job.

WALLS

Generally 38x140mm ELS studs at 600 C/C with OSB sheathing.

FLOOR JOISTS

Steico-engineered I-beam floor joists cut to size at centres to engineer’s details.

FLOOR DECK

Sub-floors to apartments and Egger resin-impregnated floorboards to houses.

FIXINGS

All fixings necessary to erect the timber frame structure in accordance with engineer’s details.

INSULATION

Kingspan TW55 insulation supplied and fixed to external walls.

INTERNAL WALLS

All internal load-bearing and non-load-bearing partitions supplied and erected.